Robots have already proved to be promising tools to complete complex and demanding maintenance tasks. While engineers have developed a wide range of robots that could help to maintain and repair infrastructure, many of these robots need to be plugged into external power sources, which limits their real-world application. Researchers at the Max Planck Institute for Intelligent Systems, Harbin Institute of Technology, and Hong Kong University of Science and Technology recently developed a new wireless miniature robot that can move through pipes and other tubular structures without relying on external sources of power.

This robot, introduced in a paper published in Science Robotics, could help to effectively solve complex maintenance problems while minimizing damage to pipes. «Wireless millimeter-scale robots capable of navigating through fluid-flowing tubular structures hold substantial potential for inspection, maintenance or repair use in nuclear, industrial, and medical applications,» Wenqi Hu, co-author of the paper, told Tech Xplore. «However, prevalent reliance on external powering constrains their operational range and applicable environments.»Many previously proposed wireless maintenance robots are bigger than their power-reliant counterparts, can operate for a limited amount of time, and have fewer functionalities.

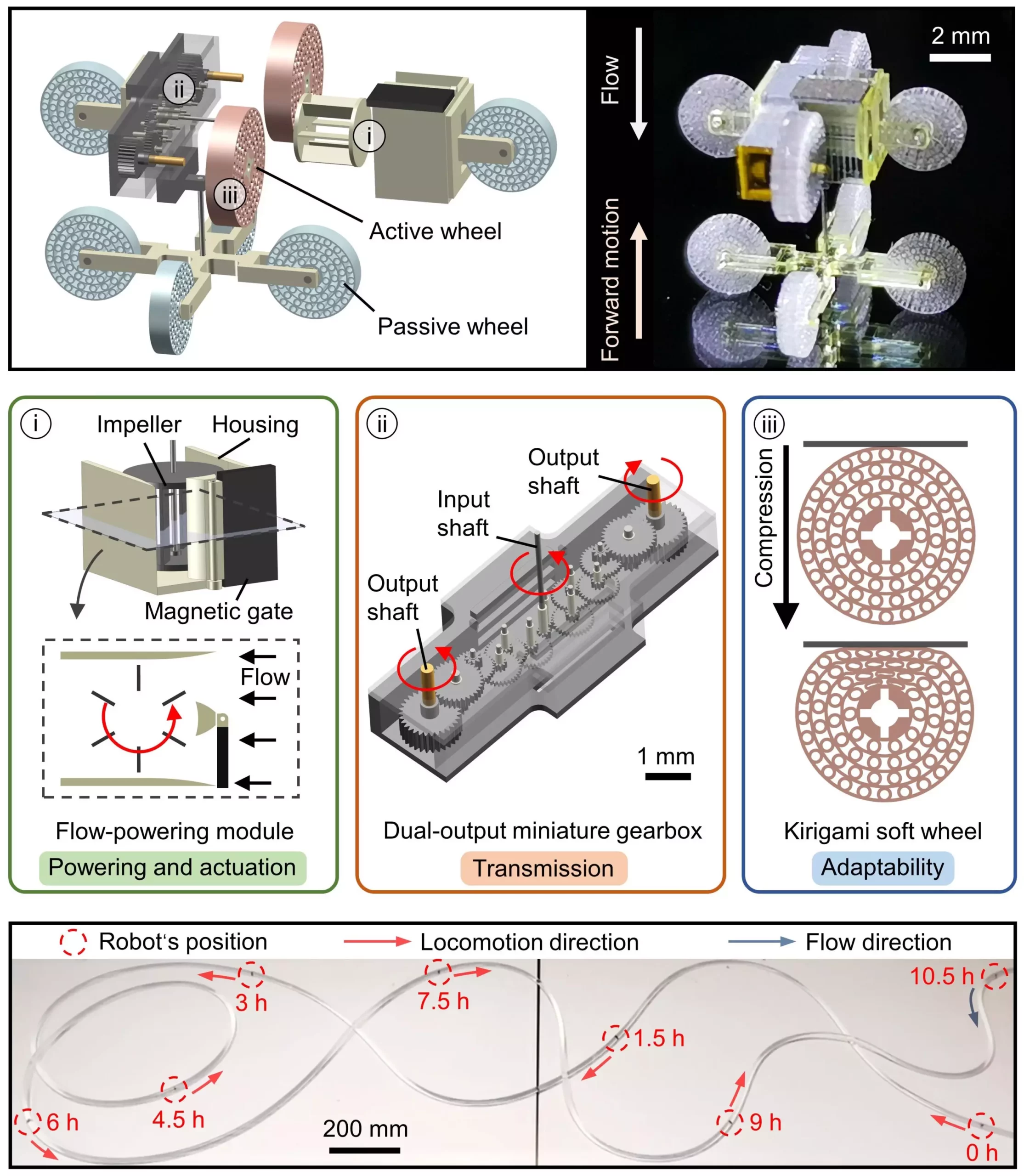

Hu and his colleagues set out to develop a wireless millirobot that includes an internal power source and an actuation unit, utilizing its available energy in a controlled way. This could allow it to cover longer distances within tubular structures and perform routine maintenance tasks for prolonged periods of time, without running out of energy. «Our robot incorporates three key components: a flow-powering module for making use of flow power, a dual-output miniature gearbox for transmitting the converted mechanical energy into the robot’s locomotion system, and kirigami soft wheels for adaptive locomotion in complex tubes,» Hu explained. «The proposed flow-powered tube millirobot offers controllable up-/downstream long-distance navigation in complex pipelines for diverse applications.»

The wheeled millimeter-scale robot created by Hu and his collaborators has an internal impeller that can convert the flow of fluids in a tubular structure into mechanical energy. Moreover, the direction in which it is moving can be modulated simply by applying an external magnetic. «Our robot addresses the needs of applications that demand long-distance navigation, as well as the ability to perform long-duration tasks within confined tubular structures that are filled with flowing gases or liquids,» Hu said.

The researchers evaluated their robot in a series of preliminary tests and found that it achieved promising results. As part of their next studies, they plan to further boost its capabilities and stability, to facilitate its future deployment in real-world settings. «Currently, the anchoring force that balances flow resistance acting on the robot’s body is provided by the wheel friction force,» Hu added. «To ensure stable locomotion in tubes with high flow rates (>1 m/s) or low-friction surfaces like oil pipelines, streamlining the robot body to minimize flow resistance or adding microstructures to the wheel surfaces to increase friction can be effective. «In addition, the robot’s motion status switching is limited by the working distance of external magnetic fields.

Deja una respuesta